Condensate Pot Manufacturer In India: Sachiya Steel International Leading the Way

Condensate pots are pivotal in maintaining the efficacy and durability of steam systems across various industries. In India, a nation witnessing rapid industrial growth, the demand for top-tier condensate pots is burgeoning. This article takes an in-depth look at the significance of condensate pots and their contributions to steam systems. It spotlights Sachiya Steel International, a renowned condensate pot manufacturer in India.

In the realm of industrial processes entailing steam, condensate pots emerge as indispensable components, ensuring the optimal functioning of steam systems. These pots act as reservoirs, accumulating and holding condensate—the liquid state resulting from steam losing heat. Effective condensate management is pivotal in averting water hammer and corrosion and maintaining the system’s efficiency.

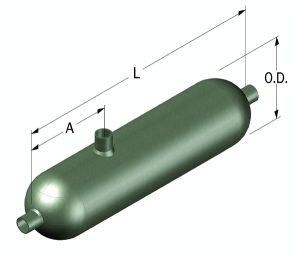

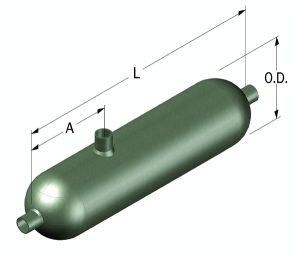

Understanding Condensate Pots

Defining Condensate Pots

Condensate pots assume the role of strategic vessels within steam systems, collecting condensate before it contacts sensitive instruments. This precludes potential damage or measurement inaccuracies due to direct condensate interaction.

Role in Enhancing Steam System Operations

Accumulated condensate within steam lines can result in substantial issues. One is water hammer—a phenomenon where rapid steam condensation leads to pressure waves capable of damaging pipes and equipment. Condensate pots offer a controlled space for gradual condensate collection, mitigating these problems effectively.

Operational Mechanism

The Inner Workings of Condensate Pots

Condensate pots operate on a straightforward principle. Positioned at low points within steam systems, they facilitate condensate collection. A connection between the steam line and the pot permits condensate ingress while steam entry is averted. Drains within the pot facilitate controlled condensate expulsion.

Countering Corrosion and Water Hammer

Beyond averting water hammer, condensate pots are pivotal in thwarting corrosion. By accumulating condensate, these pots diminish the likelihood of corrosive agents contacting sensitive equipment.

Critical Attributes of High-Quality Condensate Pots

Material Selection Strategies

The choice of materials significantly impacts condensate pot performance and lifespan. Superior stainless steel and corrosion-resistant alloys are favoured due to their resilience in the demanding steam system environment.

Precision in Design and Construction

Meticulous attention to fluid dynamics and pressure conditions shapes the design of quality condensate pots. This design ensures smooth condensate collection and drainage, minimizing potential blockages.

Efficient Drainage Strategies

Effective drainage mechanisms are integral to preventing condensate accumulation. Well-designed condensate pots feature robust drainage systems, facilitating timely condensate removal.

Sachiya Steel International: A Leading Condensate Pot Manufacturer

In the landscape of condensate pot manufacturing, Sachiya Steel International shines as a preeminent player. The company is synonymous with innovative designs and an unwavering commitment to quality.

Selecting the Ideal Condensate Pot

When selecting a condensate pot for a specific steam system, certain factors need to be considered:

Aligning with System Prerequisites

Distinct industrial processes translate to varying condensate handling requirements. Choosing a pot that aligns with the specific system needs is pivotal.

Tailored Solutions for Varied Needs

Prominent manufacturers, including Sachiya Steel International, offer tailored options to match the unique demands of individual applications.

Installation and Upkeep

Proven Installation Guidelines

Correct installation procedures are paramount for optimal condensate pot functionality. Adhering to manufacturer guidelines ensures desired outcomes.

Ensuring Longevity through Routine Maintenance

Regular maintenance, encompassing inspection and cleaning, is imperative to prolong the condensate pot lifespan and sustain system efficiency.

Advantages of Utilizing Condensate Pots

Augmented System Efficiency

By curbing water hammer and corrosion, condensate pots contribute significantly to overall steam system efficiency and dependability.

Safeguarding Equipment Integrity

Condensate pots shield sensitive instrumentation from the potentially deleterious effects of direct condensate interaction, ensuring accurate measurements and equipment durability.

Tackling High-Temperature Conditions

Steam systems operating at elevated temperatures demand condensate pots that withstand heat without compromising structural integrity.

Mitigating Corrosion Challenges

Corrosion is a common adversary in steam systems. Employing high-quality materials and adhering to proper maintenance regimens helps counteract corrosion-related issues.

Future Trajectories in Condensate Pot Technology

Integration of IoT and Smart Sensors

Anticipated trends encompass the integration of Internet of Things (IoT) technology and smart sensors to enhance monitoring and control capabilities.

Sustainable Manufacturing Approaches

As environmental concerns gain prominence, manufacturers will likely embrace sustainable condensate pot production practices.

Conclusion

Condensate pots are pivotal in maintaining efficient and reliable steam systems within India’s burgeoning industrial landscape. These vessels effectively ward off water hammer and corrosion and facilitate accurate measurements, thereby contributing to the overall efficiency of industrial processes. By selecting premium condensate pots from esteemed manufacturers like Sachiya Steel International and abiding by recommended installation and maintenance protocols, industries can optimize their steam systems for peak performance.

FAQs

What role does a condensate pot play in a steam system?

A condensate pot collects and holds condensate, preventing water hammer and corrosion and safeguarding sensitive equipment.

How does material selection impact condensate pot quality?

Materials like robust stainless steel resist corrosion and withstand demanding steam system conditions, ensuring extended pot lifespan.

Are condensate pots customizable to specific needs?

Leading manufacturers offer tailored solutions to match diverse industrial requirements.

What benefits do condensate pots offer to system efficiency?

Condensate pots curtail water hammer and corrosion, heightening overall steam system efficiency and reliability.

What lies ahead for condensate pot technology?

Future trends encompass IoT integration for enhanced monitoring and sustainable manufacturing practices to align with environmental concerns.

Condensate pots

Condensate pots are pivotal in maintaining the efficacy and durability of steam systems across various industries. In India, a nation witnessing rapid industrial growth, the demand for top-tier condensate pots is burgeoning. This article takes an in-depth look at the significance of condensate pots and their contributions to steam systems. It spotlights Sachiya Steel International, a renowned condensate pot manufacturer in India.

Product Brand: Sachiya Steel International

Product Currency: INR

Product Price: 100

Product In-Stock: InStock

5